MDO(Machine Direction Orientation) refers to the machine direction stretching, namely longitudinal stretch. MDO can improve the transparency and gloss, stiffness, tear strength, barrier performance of the film, and help to produce film with uniform thickness, which better meet the requirement of mono material recycle packaging for the surface PE, and solve various technical problems of surface PE in printing, laminating and pouch-making processes.

TOPS FILM ensures both packaging performance and environmental protection property of the materials through coating, co-extrusion or other processes. Good barrier performance can achieve low oxygen and water vapor transmittance, which plays a good role in protecting the contents of the package. At present, MDOPE film has a wide range of applications in recyclable packaging, label film and aluminum-free dairy product packaging. Our leading products and professional technology can help you become a leader in the field of sustainable packaging.

Excellent equipment & better effect of roll film

MDOPE film has high tensile strength, excellent flatness and printability. It can maintain stable processing stability in subsequent printing, laminating, coating and pouch-making processes.

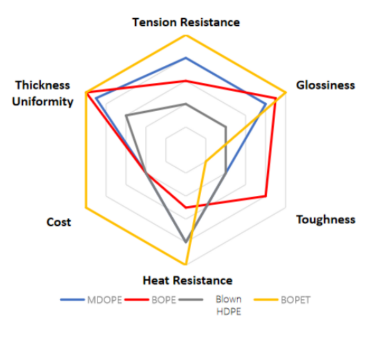

TOPS FILM’s eminent MDOPE film has good printing performance as PET, which can completely replace PET as the printing material of the surface layer, and is the best material for mono material recyclable packaging.

Film can be tailored to meet specific requirements such as high transparency and gloss, low or high haze etc.

Provide good barrier performance to improve the poor barrier of ordinary recyclable packaging, and expand the application range of recyclable packaging;

Enable the production of thinner films while retaining the same barrier properties of thicker films, it means that require less materials, less packaging and less transportation costs, thus reducing CO2 footprint, while retaining and improving film properties.

Film enters the MDO stretching unit and is evenly preheated to a required temperature.

Common PE films perform high strength, high stiffness, heat resistance, easy tearing at MD and high transparency. It is suitable for the printing layer of mono PE packaging replacing PET.

Thickness:20-40um

Width:500-2200mm

High barrier MDOPE has coating barrier layer or extrusion barrier layer, achieving excellent oxygen barrier and aroma preservation.

Thickness:20-40um

Width:500-2200mm

Extremely high barrier MDOPE film performs excellent water vapor barrier property. Special formula films enhance both oxygen barrier and aroma preservation. It is available for product packaging with higher requirement on shelf life.

Thickness:21-40um

Width:500-2200mm

Please provide the following details to help our sales represent to understand your needs, and get in touch with you as soon as possible